|

|

|

|

|

|

|

BMW Garage | BMW Meets | Register | Today's Posts | Search |

|

|

BMW 3-Series (E90 E92) Forum

>

My CBU cleaning experience

|

|

| 11-15-2014, 09:24 AM | #1 |

|

New Member

25

Rep 18

Posts |

My CBU cleaning experience

Morning y'all, before I give you a brief run down of my experience with CBU cleaning, I want to recognize Mik325tds for his assistance in this adventure. With that said, here goes...

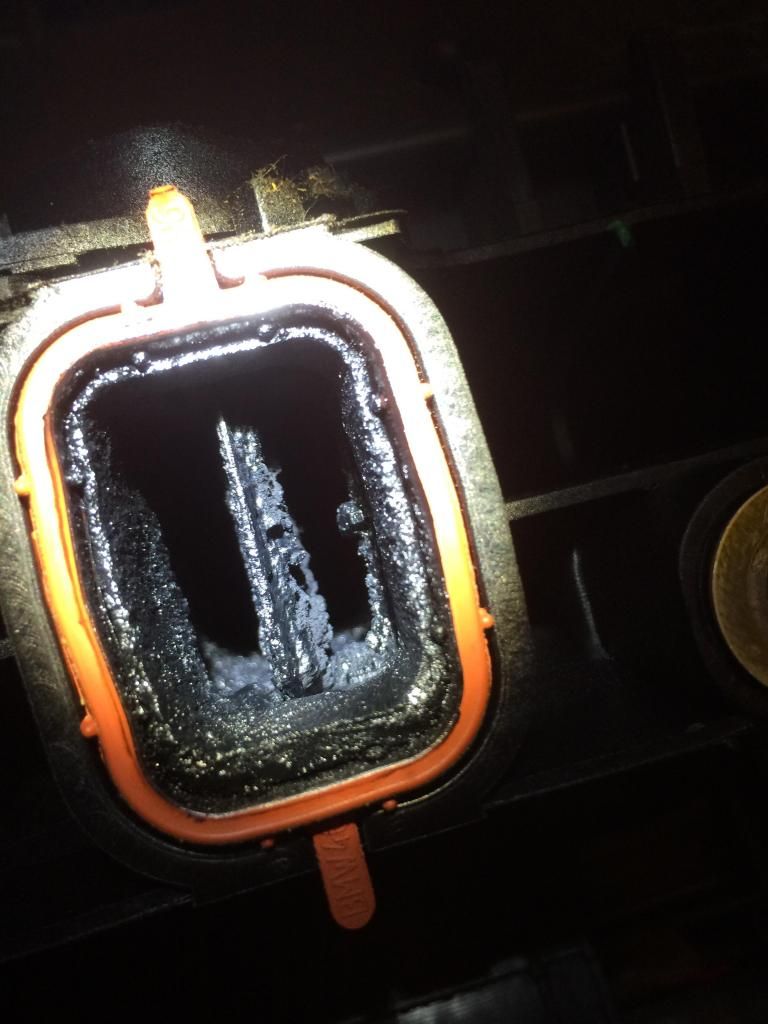

BLUF: at 51K miles my intake track had significant CBU blockage. Cleaning it restored the power it once had. In my opinion, this is a must for anyone over 40K miles. Read on for specifics. Specs: 2011 335D w/51K miles. Previous owner routine service completed by the dealer. The last service completed was at 50K miles. I took ownership a month ago and like I do with all my cars, I do as much preventative mx as possible prior to driving on a regular basis. So, the CBU issue had to be addressed up front. Oh and 4 days prior to taking ownership, I test drove a similar 2011 335D and it had a much stronger power band; however, it only had 28K miles on the clock. So this of course went into my thought process as I researched and finally decided to do the cleaning. How I did it: After removing all the necessary covers and such that hide the intake manifold, the actual removal of the intake was quick and easy. Now keep in mind I've been wrenching on cars for most of my life (not a mechanic though, just something I like to do) Anyway, to remove the intake is fairly straight forward and only requires the basic tools. There are write-ups on that process so I wont cover it here. After removing the intake, EGR valve, and throttle body, it was apparent the CBU issue is a real problem. I didn't measure the amount of blockage for each runner; however, suffice it to say a picture is worth a thousand words. Now, I didn't have a fancy sonic cleaner so I did the next best thing, I washed it with hot water, degreaser and soap. The process I used was as follows: (be sure to remove the EGR/throttle body, swirl flaps and sensor from the intake before you start this process. Bottom-line you want to remove everything from the intake). If you have access to a pressure washer great, if not, don't worry you can still clean the intake. I used a pressure washer with the normal nozzle (with cold water at first (if I did it again, I'd of used hot water to start because hot water cuts through a mess much faster)). I used a couple clamps to secure it to a wood pallet. Blasted it for a few minutes then proceeded to step two. For step two, take a normal sized plastic trash can, fill it with hot water, degreaser/soap mix and let the intake soak for 2-3 hours (I also placed a plywood cover over the top to hold the heat in). After the soak, repeat the pressure washer phase using hot water if possible. Then empty and refill your trash can with new hot water degreaser/soap mixture. Let sit again for 2-3 hours. After soaking again, pressure wash again with hot water. For me, two cycles was all that was needed. My intake was 99% clean. Next I had to address the EGR and throttle body. fortunately for me, I have a small cabinet blaster loaded with Soda for media. Using the soda media took a little longer to remove the carbon but it was gentle enough that I didn't have to worry about hurting anything. I also used the soda to blast the swirl flaps as well and would not use anything more abrasive than soda on the plastic flaps. Of course if you don't have access to a blasting cabinet then you will need to use the soap water solution for the swirl flaps. I used air from my compressor to ensure all the soda was removed. If you're not familiar with Soda blasting, its very fine media unlike sand or walnut shells that is courser and will remove material at a much faster rate. Now that my intake, egr and throttle body were cleaned, I had to focus my attention to the cylinder head. I purchased a cheap usb fiber optic camera on a 15 foot tether (it worked after I modified it. had to remove the lens case as it was too thick to get fully into the valve ports). What was nice about the USB camera, I could capture the pictures for analysis. Unfotunately when I started to clean the valves, the camera broke and because I was on a tight time table, I went to homedepot an picked up a cheap $99 Ryobi fiber optic camera. Boy of boy was it 100x better image quality and ease of use. if you don't own one, make it a priority. Well worth the $. Anyway, the tools used were from the SIB released on CBU cleaning. Mik325tds was kind enough to allow me to rent all the required adapters and wands. I purchased my fine grade walnut shells from harborfrieght (25# for $24. I ended up reusing them several times with no issues. Some may scoff at this but I couldn't care less. That's how I did it and its how I'd do it again! Of course, I have a blasting machine, air compressor and shop vac. With all the right tools, the process was simple and pretty easy. I used the Ryobi camera to ensure my valves were closed and to validate the cleaning was done to an acceptable level. To close the valves, you will need to bump the starter by either purchasing a cheap jumper switch or do like me and wire up an old light switch. It was a crude setup but it worked. As you may know the starter has a continuous 12v hot and a circuited 12v. You wire one end of your switch to a 12v source and the other to the circuited 12v. Then bump your switch to engage the starter. If you jockey your camera right, you can watch the valve open and close while you bump the starter. Easy stuff guys! ***As you do this, be careful, the walnut shells will burn through plastic. So when cleaning the top ports, make sure you have your wands in the head far enough. you don't want to allow the media to clean the plastic valve cover. After several hours, I was done. I wont lie, the job was long and boring. Dirty too! I used some thin mil plastic painter cloths to cover the entire engine bay. This kept the dust and inevitable mistakes of media fall out from getting into places I didn't want it to go. Also be sure to tape off every port not being cleaned. Once cleaned and media removed (check and verify with the Ryobi camera) tape it off to prevent any shells from accidentally entering the port. Again, its a laborious process but its easy. Take your time. The old adage measure twice and cut once does apply here. If your not sure what an open or closed valve looks like, leave your camera in the port and engage the starter for several seconds to see the valve open and close. Once you see it, you'll know what to look for. The CBU cleaning was now done. Now I wanted to prevent it from returning. So I then fabricated a piece of thin sheetmetal to place between the cooler and the EGR valve. I will eventually remove the cooler but for now I'm just blocking on the one end. I used a little silicone to seal the side that doesn't have a factory seal. The final phase to my project was installing the meth kit. I purchased a Devils own stage 2 progressive controller kit. Its a universal kit with a 2.5 gal tank. I plumbed the line pre-IAT on the cold side charge pipe (with the bottom tray removed, the charge pipe is simple to remove as you can see the clip which holds it in place with the inter cooler). I also plumbed another 1/8 hose barb in the charge pipe to pull my boost reading for the progressive controller. The Meth install too a little while to install but it was not hard. Just time consuming because I wanted it to be hidden for the most part. So, there is a lot of information here and some of it may be a little confusing so please feel free to ask me questions and I'll answer the best I can. Oh and to answer the big question...did the cleaning make a difference in power. ABSOLUTELY! Not using the meth, the power was back. If you have 40+K miles, then this is a service you need to start thinking about. I have put 500 miles on the car since cleaning and all is running great. Of course I get the EGR codes every time I start the car but for now, I use my torque app to clear the code. Not a big deal if you have an extra 30 seconds every time you drive. I've owned a lot of nice cars and while the 335D is not an all out sports car, its the nicest commuter with a decent sports car feel that I've owned. It has comfort, power and pretty good handling for an everyday driver. The fuel economy is outstanding, I commute 110 miles round trip daily in the DC metro area and the first fill up has me at 40 mpg avg. Bottom line, its a keeper!                                  |

| 11-15-2014, 09:52 AM | #2 |

|

Brigadier General

411

Rep 3,051

Posts

Drives: 2009 BMW 335d

Join Date: Jan 2012

Location: Toronto, ON, Canada

|

Damn! Meth kit going forward. I like.

Great before and after pics man. |

|

Appreciate

0

|

| 11-15-2014, 10:24 AM | #3 |

|

Captain

143

Rep 631

Posts |

Great write up. Probably more than most (including me) can tackle. I just had mine cleaned at the dealer at 53K miles. Power and MPG was restored.

Last edited by kbsilver; 11-15-2014 at 03:27 PM.. |

|

Appreciate

0

|

| 11-15-2014, 10:40 AM | #4 |

|

Captain

165

Rep 730

Posts |

You did an amazing job cleaning the CBU. And thanks for the detailed instructions.

I am curious to see if the Meth kit will keep the intake clean over time. Please report your finding |

|

Appreciate

0

|

| 11-15-2014, 10:59 AM | #6 |

|

New Member

25

Rep 18

Posts |

I thought I had taken more valve photos after cleaning but apparently I didn't. Nevertheless, they're all clean now. The job wasn't that challenging but I'll caveat that with the understanding I've tackled projects such as the dreaded 911 IMS bearing, porting an 03 Cobra Eaton Supercharger, swapping a VR6 into a 92 GTI, and building cars like the one below from the ground up since I was in grade school (which has been a while ago ;-).

|

|

Appreciate

0

|

| 11-15-2014, 11:03 AM | #7 | |

|

Colonel

617

Rep 2,408

Posts |

Quote:

A really quick way to use Torque to reset that pending code is to put the "Fault Clear" button on one of your gauge displays (see pic for an example). Then when you get to your destination and shut off your car you can hit the start/stop button a couple times to get the ignition on but not started (on my car Torque won't clear codes unless I'm in ignition on but engine off), then tap the "Fault Clear" button on the Torque App, and you're good to go. Takes about 5 seconds this way. And for those that don't know, If you do this everytime then you never see the SES light as it only sets a "pending code" on the first key cycle which does not trigger the SES light.

__________________

2011 335d 11.68 @ 125.71 mph 1/4 mile NHRA certified track

Ram Cummins with lots-o-mods |

|

|

Appreciate

0

|

| 11-15-2014, 12:37 PM | #10 |

|

New Member

25

Rep 18

Posts |

@ dixy2k, I sure did. Would it have been easier with the head off, sure. Was it necessary nope. Just take your time, have a good air compressor, bore scope, shop vac, tools etc... and anyone with a little ambition can accomplish this procedure. I've learned to do lots of research before the project and after the project, double check your work. With that said, I have a few gearhead buddies who I bounce ideas off of on a regular basis (Trev that's you bro...here is some of his work http://forum.e46fanatics.com/showthread.php?t=1021487)

|

|

Appreciate

0

|

| 11-15-2014, 12:57 PM | #11 |

|

New Member

25

Rep 18

Posts |

|

|

Appreciate

0

|

| 11-15-2014, 01:43 PM | #13 |

|

Captain

165

Rep 730

Posts |

Lee4him, is it possible to do some cleaning of the intake runners on the head with flexible brush if I do not have a special wand and a big compressor?

|

|

Appreciate

0

|

| 11-15-2014, 07:11 PM | #14 |

|

New Member

25

Rep 18

Posts |

@ montr, possible, sure...effective I don't think so. Cleaning the gunk out will be problematic because of the oil, it sticks and smears on everything. I believe you'd find yourself getting very frustrated very quickly. The other issue is ensuring all the dislodged carbon and gunk (large pieces) is removed so that you don't pass it through the valves. I try lots of crazy stuff but cleaning only with a brush would not be one of them. If you don't have the equipment then go with the Water/meth injection and egr block. It'll take longer but will help.

|

|

Appreciate

0

|

| 11-15-2014, 07:35 PM | #15 | |

|

Banned

109

Rep 429

Posts |

Quote:

|

|

|

Appreciate

0

|

| 11-16-2014, 07:45 AM | #17 |

|

New Member

25

Rep 18

Posts |

@ 2deerwhistlers, I understood the egr cooler cracking issue to be caused by significantly increased EGTs seen after major mods were applied to increase hp/tq. My understanding was that to apply a block to the EGR valve side on a stock application would not be hazardous to the cooler. Of course I haven't been on this board but a few weeks now so if I'm wrong, please let me know. With that said, does anyone have the number of failed coolers on our cars? Is it one, ten, fifty?

After saying that, my plan today is to fabricate a block off plate and if time permits, I'll install it. I do believe that its a good idea to take the cooler out of the equation but for short term stock applications a block off plate at the valve end will work. Please correct me if I'm wrong. |

|

Appreciate

0

|

| 11-16-2014, 09:38 AM | #18 |

|

Private First Class

39

Rep 180

Posts |

I installed my meth nozzle after the intercooler, is there any advantages to installing it before? I'm guessing one should be able to run a larger nozzle with less chance of quench placing it before? I did not clean CBU in the intake, only the EGR before installing kit, so my thoughts were closer to the intake the better,(cleaning purposes)

|

|

Appreciate

0

|

| 11-16-2014, 10:30 AM | #19 |

|

New Member

25

Rep 18

Posts |

@ GTP900, The link below explains the different locations one could install the nozzles.

http://www.alcohol-injection.com/en/...jection-nozzle I went pre-IAT based on the info below. from DevilsOwn website: "Most computer controlled engines have an intake air temperature (IAT) sensor. This sensor monitors the temperature of the air going into the motor. The reason for putting it before the IAT sensor is because it will see the cooler temps and the engine will advance timing, allowing for more power. Also placing the injection nozzle as far from the cylinders/air intake sensor as possible, it allows for the water/methanol mixture to be better absorbed into the intake air charge. This allows for great distribution to each cylinder. This post intercooler nozzle location should be the primary nozzle location to be considered for most users. In theory, since the air charge will be mixed for a longer distance, and therefore time, allowing for the moisture to be absorbed by the air, creating the coolest possible air charge going into the cylinders. Water/methanol molecules from a nozzle located here have more time to be absorbed by the intake charge exiting the intercooler before making it into the combustion chamber." |

|

Appreciate

0

|

| 11-16-2014, 10:46 AM | #20 |

|

Rudolf/German/Compression Ignition Specialist.

53

Rep 168

Posts |

Great post excellent work... Just a precaution.... Stay as far away as you can from brillow pads, scotch brite pads etc if your going to clean anything intake or engine related, head etc. The bearings in our cars are hardened and do not embed particles in them. Older bearings had large amount of lead in them to help aid in contamination, new engines due to the pressures and environmental laws cannot. Thus the reason european 3 series diesels use a different bearing set up than n.a. Scotch brite pads work great however they do break down. I have seen a few industrial cummins engine come through my shop for warranty get rejected due to oil contamination/damage from scotch brite pads. Guys will send the engine to a local shop "no problem we can rebuild it for way less than the dealer" less than 5k on the engine total failure.

I will be doing this procedure in the spring however I am pretty sure I will send the intake out for ultra sound cleaning and purchase the walnut blaster kit just to be sure... There is a reason bmw recommends this procedure over others. Great write up! |

|

Appreciate

0

|

| 11-16-2014, 11:24 AM | #21 |

|

Kind of a Big Deal

171

Rep 857

Posts |

lee$him excellent post and great photos.

+1 re nice to have another 335d local. Were you are the NCC DIY yesterday at Excluservice by any chance? Any chance you can post the dimensions for the EGR block-off plate as I an getting ready to make one? |

|

Appreciate

0

|

|

| Bookmarks |

|

|