|

|

|

|

|

|

|

BMW Garage | BMW Meets | Register | Today's Posts | Search |

|

|

BMW 3-Series (E90 E92) Forum

>

Vishnu N54 Fuel System Research Part 1

|

|

| 04-07-2011, 12:25 AM | #1 |

1806

Rep 17,960

Posts

Drives: A Lot

Join Date: Sep 2006

Location: SF Bay, CA

iTrader: (0)

Garage List 2018 Ducati Panigal ... [0.00]

2016 Mazda CX5 [0.00] 2017 Aprilia Tuono ... [0.00] 2019 BMW M2 Competi ... [0.00] 2015 BMW M5 Competi ... [10.00] 2016 Ducati XDiavel S [0.00] 2016 AMG GT S [0.00] 2011 Ferrari 458 It ... [0.00] 2017 Charger Hellcat [0.00] 2015 KTM Super Duke ... [0.00] 2016 KTM RC390 [0.00] |

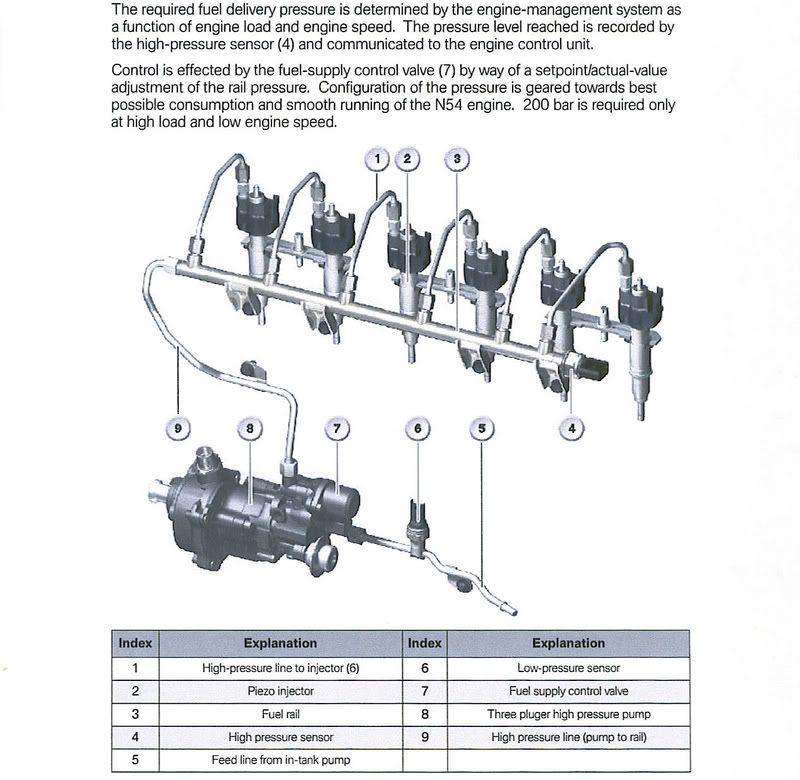

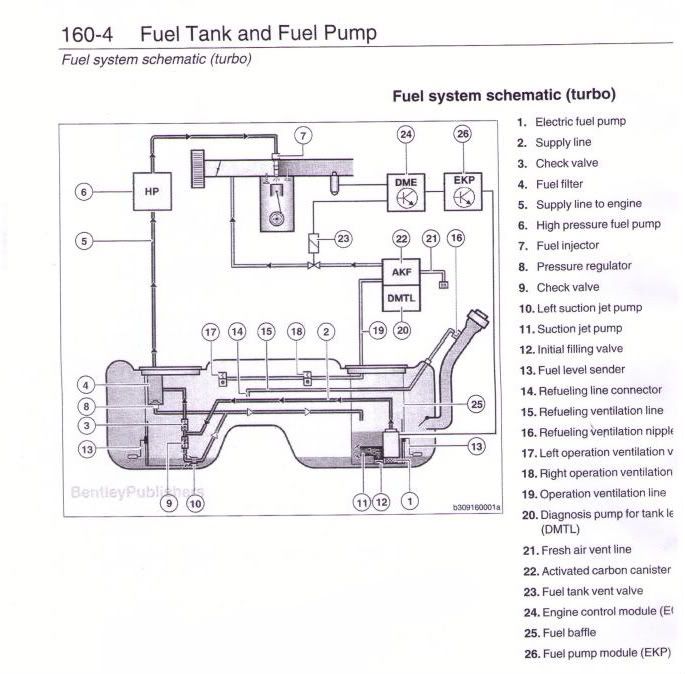

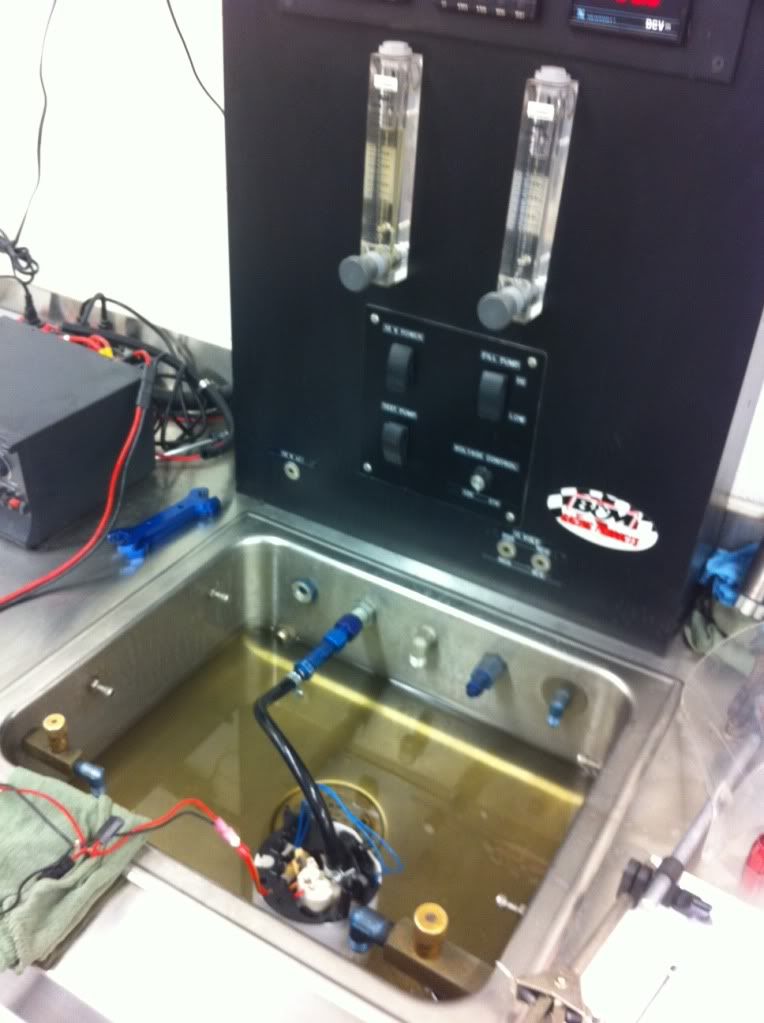

Hi guys,

For quite some time now, we’ve been quietly determining the limitations and weaknesses of the n54’s fuel system. Since it’s very different from the conventional fuel systems found in other cars, there was a lot to test and even more to learn. And much of it was surprising! Looking at things from a tuning perspective, the need to evaluate the limitations of the factory fuel system were even more of a priority considering that even the mildest of tunes results in 60hp gains with no associated hardware/component changes. Understanding BMW’s Direct Injection Fuel System Anyone familiar with conventional fuel injection systems will find some comfort in knowing that our BMW fuel system is actually quite traditional. At least the first half of it is. It consists of 6 components that play key roles: Low Pressure Fuel Pump Low Pressure Fuel Pump Controller Fuel Pressure Regulator Fuel Pressure Sensor High Pressure Fuel Pump Fuel Injectors   Low Pressure Fuel Pump (LPFP)  As with other conventional fuel injected applications, this assembly sits submerged in the fuel tank. It is accessible through an airtight lid which is located under the rear passenger seat cushion. The main function of this device is to pump fuel from the fuel tank, under the car, and to the High Pressure fuel pump which is then used to pressurize the fuel rail which distributes fuel to the fuel injections. But there’s a bit more going on behind the scenes. First, the pump sits in a bucket. And this bucket is spring loaded to sit firmly pressed against the bottom of the tank. This bucket performs the roll of ensuring that the fuel pump’s pick-up stays submerged in fuel. Even when the fuel level is low or even during hard cornering where fuel sloshes to the side of the tank. In fact, even when the fuel tank is nearly empty, you will find that the bucket is often completely full. Without this function, the fuel pump would suck in air bubbles which can be stressful for pump internals and even cause engine running issues such as misfire. Those familiar with more motorsport focused fuel systems know that such system often employ two (or more) fuel pumps. One main pump and one (or more) smaller “lifter” or “transfer” pump(s) which simply move fuel from the corners of the fuel tank into the bucket houses the main pump. Miraculously, the low pressure fuel pump assembly in our BMW accomplishes all these important functions with just 1 pump. This eliminates the need for additional wiring, heavier duty electronics, more plumbing and more pump hardware. This is cleverly accomplished by a small secondary pressure port in the low pressure fuel pump. This secondary port is located at the bottom of the bump body. It’s internally restricted so only a relatively small amount of fuel is pushed out of it. This pressurized stream of fuel is routed through a fancy-looking plastic fitting which is mounted at the bottom of the bucket, right over a one-way flapper door. In this fancy fitting is a Venturi jet (Suction jet pump in BMW speak) which increases the velocity of the fuel (by gradually reducing its diameter). Through the wonderful world of physics, this higher velocity stream of fuel is used to create a localized low pressure zone which is used to pull fuel upwards (against gravity) through the one way flapper door and into the bucket. Without this mechanically generated low pressure zone, the fuel level in the buck would be equal to the fuel level of the fuel tank which would be unfortunate when the fuel level of the tank is low. With these systems in action, the level in the bucket is high enough to keep the fuel pump pick-up fully submerged. Once the fuel is pushed out of the bucket by the low pressure fuel pump, it is routed towards the engine bay. But not before it passes through the fuel pressure regulator. Fuel Pressure Regulator (FPR) This device is located on the other side of the tank, under the driver’s side rear seat cushion. It’s job is to ensures that the entire low pressure fuel system (from the outlet of the low pressure pump to the inlet of the high pressure fuel pump is pressure regulated to a steady 5 bar (72psi) of pressure. The excess fuel that is bypassed by the regulator is then sent back to the other side of the fuel tank and dumped back to where it is needed most-- back into the bucket. But during its return trip it is pushed through another Venturi jet fitting, this time dragging fuel from the other side of the saddlebag-shaped, over the hump in them middle, and back into the fuel pump bucket. Which means that not only does the bucket stay filled, its side of the fuel tank is always at a higher level than the other side. Low Pressure Fuel Pump Controller (EKP)  As you would expect, turning on the fuel pump in the BMW is a bit more complicated than using a simple $5 fuel pump relay to activate when the engine is running. Instead of turning the pump on or off, the Low Pressure Fuel Pump Controller (EKP in BMW-speak) constantly changes how hard it is driving the pump based upon engine demands. It does this by constantly adjusting the pump voltage between 3 and 11 volts. The higher the voltage, the faster the turbine in the fuel pump spins and the more fuel volume it pumps. Traditionally, such fuel pumps only had one speed which was ON (full voltage). Which means that it was always pumping at full speed. Which meant that the fuel pressure regulator played a bigger role in regulating fuel system pressure. This mean that during conditions of low fuel demands (ie, low load, cruise, idle, etc,.), most of the fuel that was pumped by the fuel pump was bypassed by the FPR and routed back to the fuel tank. The downside of this is that you had a bunch of extra fuel flowing needlessly. Not only does this heat up the fuel, it also results in excessive vaporization which contributes to increased fuel tank emissions. So over time, most manufactures implemented a two stage fuel pump control circuit. So that at periods of low fuel demand, the pump would be driven at just 5-6v. And then at a full 11-14v when the engine is under load. Of course, leave it to BMW to take this one big step further by constantly varying the fuel pump voltage (by PWM control) based upon feedback it gets from the DME which is constantly monitoring the fuel pressure through a fuel pressure sensor mounted at the end of the low pressure fuel system (just upstream of the HPFP). In fact, the EKP modules acts much like a conventional boost control system. But instead of PWM controlling a boost control solenoid based upon boost pressure, it PWM controls the pump based upon fuel pressure. Clever! Which means that the pump only flows close to what the engine needs, reducing the amount of fuel that is returned to the fuel tank by the FPR. High Pressure Fuel Pump (HPFP)  The most criticized component in our car. For something so finicky, it’s role is actually very straight-forward: To accept the fuel that is being fed to it’s inlet (regulated to 72psi) and to “step it up” to 1000-4000psi at its outlet in the fuel rail. As you would expect, this takes quite a bit of power to do this (probably a few HP). Which is why the HPFP is driven directly off of the engine and not fully powered by an electrical control system. Unlike the low pressure fuel pump, this pump's speed cannot be controlled based upon demand as it’s always spinning at a fixed ratio with engine RPM. Which means that another device must be used to regulate fuel rail pressure. And this is where the fuel supply control valve comes into play. Unlike an FPR which regulates fuel system pressure by controlling the rate of fuel return, the supply control valve regulates fuel rail pressure by controlling the amount of fuel going into the HPFP inlet. This valve is controlled by the DME which monitors fuel pressure through a sensor mounted in the fuel rail. The DME establishes the fuel pressure target from internal calculations based upon calculated cylinder pressure, engine speed, etc. All things equal, the higher the cylinder pressure, the higher the fuel rail pressure. This direct relationship ensures that the Fuel Injector “squirts” travels far enough into the combustion chamber during the compression stroke to initiate the desired optimal burn. The more boost pressure, the higher the cylinder pressures. The higher the cylinder pressures, the higher the desired fuel rail pressures. Pretty simple. Mapped properly, this results in better fuel economy, lower emissions and more engine torque. More Thoughts So all this begs a few question which we hope to answer in depth in Part 2 of this tech series: What is up with all these failed HPFPs? Are they really that poorly designed/built? Or are other issues contributing to their failure? Or are some of these HPFP failures are being misdiagnosed? BMW has had many attempted fixes for this ongoing problem. First, they just replaced HPFP units. After this didn’t address the problem, they redesigned the pump. A few times. Then, they reprogrammed the DME so that it would “prime” the low pressure fuel pump system to ensure full pressure (72psi) at the HPFP inlet (before it started to spin) which suggests that they believed that pump cavitation may have been a potential cause of failure/wear. Next in Part 2.... Bench testing results are in... Stock vs UPGRADED Fuel System Show Down  |

| 04-07-2011, 12:27 AM | #2 |

|

Major General

288

Rep 5,064

Posts

Drives: Black e92 335i

Join Date: Apr 2010

Location: Brampton, Ontario

|

__________________

JB4 / OSS Angel Eyes / Downpipes / F1-Racewerks FMIC / Custom Meth Kit / BMS DCI / ER Chargepipe / HKS BOV / BMS Meth Elbow / BMW Performance Exhaust / Carbon Fiber Inlay Quad Tips / 19" Miro 111 / Front Aero Lip / M3 Sides / VRS CSL Trunk / Mtech Rear / DD CF Quad Finned Diffuser / LCI Tails / BBK / Smoked Reflectors / F1 Euphoria LED Interior / License LED's / GT 5000k Corners / 5000k HID Fogs / Air Scoops / LED Turn Signals / FK Silverline Coilovers / HPA endlinks / Vibrant Resonators / Osram CBI 5000k D1S

|

|

Appreciate

0

|

| 04-07-2011, 12:28 AM | #3 |

|

Private First Class

4

Rep 177

Posts |

Great work!

__________________

2008 E90 335i | PROcede Rev 2.5 | PWM Meth | CP-E FMIC + OC | AR catless ceramic DP | BMS DCI | Wavetrac LSD | MORR MonoForged VS8.2 | Michelin PSS

|

|

Appreciate

0

|

| 04-07-2011, 01:08 AM | #10 |

|

Brigadier General

398

Rep 3,159

Posts |

So are you saying, modify the voltage to the rear pump, put in a higher volume pump in the rear tank and away we go?

__________________

2015 M3 BPM Tuned, Eibach, Magnaflow and more www.tmrmzine.com/m3/f80

SOLD E92 Slēk Carbon Fiber Widebody M3 www.tmrmzine.com/m3/slek/ SOLD E92 335i Stage 3+ with all the toys www.tmrmzine.com/335/ SOLD E39 M5 Modded, What a great car! www.tmrmzine.com/m5/ |

|

Appreciate

0

|

| 04-07-2011, 01:37 AM | #13 |

|

FREE DREAMK

164

Rep 9,321

Posts

Drives: the shiiit!

Join Date: Aug 2009

Location: Vineland, NJ

|

good read and good to know.

now about that meth kit....

__________________

|

|

Appreciate

0

|

| 04-07-2011, 01:38 AM | #14 |

|

Banned

118

Rep 4,771

Posts |

|

|

Appreciate

0

|

| 04-07-2011, 01:40 AM | #15 |

1806

Rep 17,960

Posts

Drives: A Lot

Join Date: Sep 2006

Location: SF Bay, CA

iTrader: (0)

Garage List 2018 Ducati Panigal ... [0.00]

2016 Mazda CX5 [0.00] 2017 Aprilia Tuono ... [0.00] 2019 BMW M2 Competi ... [0.00] 2015 BMW M5 Competi ... [10.00] 2016 Ducati XDiavel S [0.00] 2016 AMG GT S [0.00] 2011 Ferrari 458 It ... [0.00] 2017 Charger Hellcat [0.00] 2015 KTM Super Duke ... [0.00] 2016 KTM RC390 [0.00] |

We really had to develop a proper fuel system upgrade before we released our PWM meth kit. We didn't want people to use our meth kit as a means to "fix" an inadequate fuel system. But rather as a method to raise octane and reduce IATs.

Shiv |

|

Appreciate

0

|

| 04-07-2011, 01:53 AM | #16 |

|

Banned

118

Rep 4,771

Posts |

Any estimated ETA on when we will receive part 2?

|

|

Appreciate

0

|

| 04-07-2011, 01:55 AM | #17 |

|

Lieutenant

50

Rep 546

Posts |

Props to Shiv and Vishnu for taking the initiative and effort to give us an upgraded fuel system!

__________________

Legal Disclaimer: Anything I or anyone else says about my vehicle on this website(1addicts.com or any affiliated or nonaffiliated sites), pertaining to modifications, is only to gain acceptance from my/our peers, and does not actually represent anything actually existing on my car, and thus, cannot be held against me in any issues, i.e. warranty claims, that may arise.

|

|

Appreciate

0

|

| 04-07-2011, 01:57 AM | #19 |

|

EUROPROJEKTZ

191

Rep 7,958

Posts

Drives: backwards

Join Date: Dec 2008

Location: San Jose, CA (Bay Area)

|

Great work Vishnu Crew!

Definitely subscribing to this! Definitely subscribing to this!

__________________

LTMW|SPEEDELEMENT|EUROPROJEKTZ

#TeamStretchNPoke  |

|

Appreciate

0

|

| 04-07-2011, 02:26 AM | #20 |

|

Major General

161

Rep 7,377

Posts |

Now this is something to look forward to especially for upgraded turbos guys!

Great work Shiv!

__________________

07 335i AT - MOTIV 750 - MHD E85 BMS flash - BMS PI - JB4G5 - Okada Coils - NGK 5992 Plugs - Helix IC - Snow Stg. 3 - Stett CP - Custom midpipes with 100 HJS Cats - Bastuck Quad - PSS10 - QUAIFE LSD - BMS OCC - Forge DVs - AR OC - ALCON BBK - M3 Chassi - Dinan CP - Velocity M rear Toe arms - Advan RZ-DF - LUX H8 - Level 10 AT upgrade

|

|

Appreciate

0

|

| 04-07-2011, 02:47 AM | #21 |

|

Formerly (-(ellblazer420

48

Rep 703

Posts

Drives: 07 E90 335i M/T, 15 F80 M3 DCT

Join Date: Sep 2010

Location: SF East Bay, CA

|

Great work can't wait for part 2

|

|

Appreciate

0

|

|

| Bookmarks |

|

|