|

|

|

|

|

|

|

BMW Garage | BMW Meets | Register | Today's Posts | Search |

|

|

BMW 3-Series (E90 E92) Forum

>

Vishnu N54 Fuel System Research Part 2

|

|

| 04-12-2011, 01:39 PM | #1 |

1864

Rep 17,960

Posts

Drives: A Lot

Join Date: Sep 2006

Location: SF Bay, CA

iTrader: (0)

Garage List 2018 Ducati Panigal ... [0.00]

2016 Mazda CX5 [0.00] 2017 Aprilia Tuono ... [0.00] 2019 BMW M2 Competi ... [0.00] 2015 BMW M5 Competi ... [10.00] 2016 Ducati XDiavel S [0.00] 2016 AMG GT S [0.00] 2011 Ferrari 458 It ... [0.00] 2017 Charger Hellcat [0.00] 2015 KTM Super Duke ... [0.00] 2016 KTM RC390 [0.00] |

Please excuse any spelling snafus, didn't have much time to proofread! So don't be too critical yet

Vishnu Fuel System Testing Part 2 Stock LPFP Flow Test Results Fuel pumps are pretty simple devices. Like many kinds of pumps, they use an internal rotor to lift fuel from the pick-up, transfer it upwards through the body and out the outlet. The more voltage you give it, the faster the rotor spins. The faster the rotor spins, the more volume of fuel it moves (measured in cc/min, liter/hr or lbs/hr). But in the case of fuel systems, they also have to be able to push fuel hard enough to create pressure at the outlet. The more pressure supported at the output, the less effective the internal rotors will be. The less effective they are, the less fuel the pump will flow. Old carburated fuel systems were only regulated to a few PSI of fuel pressure which made the job of fuel pumps very easy. They didn’t do much more than transfer fuel from one part of the fuel system to another. With EFI (Electronic Fuel Injection), fuel system pressure raised to a much higher, standardized and somewhat arbitrary 43psi. This pressure increase was done to improve the injection accuracy and precision. The more pressure behind the fuel injection squirts, the less injector on-time (in milliseconds) is necessary to delivery the necessary fuel mass to the intake port. The higher pressure also improved the atomization characteristics of the fuel. The finer the spray, the better it would swirl with the air in the combustion chamber, creating a burn-friendly homogenous air/fuel charge. The fuel rail pressure wasn’t static at 43psi however. Since it was injected in the intake manifold that would routinely pull vacuum (less than atmospheric pressure), the fuel rail pressure had to be compensated or else will flow more fuel than desired. To compensate for the pulling force the manifold has on the fuel, the manifold-referenced fuel pressure regulator was designed. Its job was to reference fuel rail pressure off of manifold vacuum. The higher the vacuum, the lower the fuel rail pressure. Conversely, with turbocharged/supercharged engines that generate positive pressure (boost), the FPR increases fuel rail pressure to compensate for the extra manifold pressure that would otherwise reduce fuel injection mass. This means if an engine is running 10psi of boost, the FPR would bump up fuel rail pressure to 10+43 or 54psi to maintain the stead 43psi pressure differential between the injector outlet (manifold) and fuel rail pressure. As you can imagine, the needs of turbocharged engines made the job of a fuel pump much harder. Not only do they have to be able supply enough fuel flow, they also have to operate at high fuel pressures! BMW Direct Injection Like standard EFI systems, BMW uses a electronically driven fuel pump and a mechanical FPR to regulate fuel system pressure. But unlike standard systems, BMW regulates pressure to 72psi, not 43psi. So right off the bat, the fuel pump in the n54 is working harder than most. Also unique is the fact that the pressurized fuel system doesn’t work all its way up to the injectors. Instead, it stops at the inlet of the mechanically driven High Pressure Fuel Pump (HPFP). The HPFP employs a DME-controlled supply control valve to control the amount of fuel that it drinks per pump rotation. By adjusting the “gulp” volume, the DME can control the fuel rail pressure (up to 4000psi!). But as you would expect given this daisy chained fuel system, the performance of the HPFP is VERY dependent on the performance of the LPFP. If the LPFP falters in any way, the HPFP doesn’t see the targeted pressure at its inlet. If this were to happen, the HPFP would be able to “step up” the pressure to the desired target. When this occurs, the DME attempts to compensate by fully opening the supply control valve. If the HPFP can’t fully compensate for the compromised LPFP, the DME responds by extending the pulse width of the fuel injectors. If the ultimate fuel flow is still not adequate, you experience an unwanted lean-run condition. We all know that lean-run conditions are undesirable, even for a Direct Injection engine that can combust happily at leaner-than-typical A/F ratios. But what are the consequences of this under-pressure issue? What effects does this have on the HPFP? When fuel demands lessen (throttle closure), how quickly does the supply control valve react to not see an overpressure condition? Does this over-pressure condition put unnecessary strain on the HPFP? Does the primary under-pressure condition cause the HPFP to cavitate? These are all valid questions and might help us get to the bottom of the chronic HPFP failures that some cars see. For a while, BMW’s explanation of the failures were based on the claim that the HPFP wasn’t compatible with fuel formulations with higher ethanol content. Which seems like a pretty huge, mostly unreasonable, oversight from a fuel pump manufacturer who should be pretty “clued-in” on the kind of fuels that are coming out of the gas station pumps. Another, more subtle, response to the failures came several months ago when BMW updated their DME software to prime the low pressure pump upon door opening. Which is done to generate the desired 72psi of fuel pressure at the inlet of the HPFP. Seems to me that this should have been done years ago. But whatever the reason is for the HPFP failures, it’s clear that we NEVER want to get into a situation where the low pressure fuel pump isn’t supplying the fuel that the HPFP is demanding. So what are the limits of the LPFP? To test this, we gathered two different pumps. One brand new (Pump 1). And the other approximately 1 year old, pulled from our shop car (Pump 2). And tested both on a flow bench. Preliminary testing was done at RC Engineering (Torrance, CA) on their fuel pump dyno. Supplementary testing was done on a customized test bench using two measurement buckets, a variable voltage power supply, an adjustable SX fuel pressure regulator (set to 72psi), a few meters of 5/16th ID fuel line a several gallons of California’s finest 91oct fuel (Shell). First, we powered the 11.0 volts. This voltage represents a 100% duty cycle condition as supplied by the Fuel Pump controller (EKP). We recorded the following flow results: Pump 1 (Brand New).... 228 lbs/hr Pump 2 (1 year old).... 204 lbs/hr At this voltage, we also measured the current draw: Pump 1.... 9.3 Amps Pump 2.... 9.8 Amps Next up, just for kicks, we dropped the pressure on the FPR to the more conventional 43psi. This has no relevance in our n54 application. But it will give us an idea of how much harder these HPFP are working in our unique 72psi environment: Pump 1.... 315 lbs/hr Pump 2.... 308 lbs/hr And current draw: Pump 1.... 8.2 Amps Pump 2.... 8.3 Amps So when running 72psi (vs 43psi), the pumps drew almost 20% more current. And lost nearly 30% fuel flow! More interestingly, the older, used Pump 2 responded more negatively than the brand new Pump 1 to the higher pressure, suggested that these LPFPs may not be capable of supporting the same maximum fuel demand over their full operational life. And when running lower pressure, both pumps offered nearly identical performance. This makes perfect sense since the pumps were less stressed at the lower pump speed. For the sake of perhaps morbid curiosity, we drove the pumps at 14v and conducted the same tests. This higher voltage environment represents a condition that cannot be replicated by the factory fuel pump controller (EPK). But something that can be accomplished with fairly simple/inexpensive circuitry that the user can install. The extra 3 volts makes the pump spin much faster. And it showed on the flow test bench: At 72psi: Pump 1.... 356 lbs/hr @ 12.2 Amps Pump 2.... 300 lbs/hr @ 13.5 Amps And at 43psi: Pump 1.... 442 lbs/hr @ 10.6 Amps Pump 2.... 430 lbs/hr @ 10.7 Amps As before, Pump 2 didn’t perform as well as Pump 1 in this test. In fact, Pump 2’s relative performance was even worse at this higher voltage, suggesting that this pump will deteriorate further as it accumulates more hours of operation. While increasing pump voltage is a common fuel system upgrade, it may be a questionable long-term solution for a already hard working pump operating at a constant 72psi. So How Does Flow Equate to Horsepower? To answer this question, we need to understand an important term: Brake Specific Fuel Consumption, or BSFC for short. BSFC a measure of fuel efficiency with respect to an engine’s power output. Or put simply, how much fuel is used to make a unit of power. The simplest accepted formula is how many pounds of fuel/hr an engine needs to make 1 horsepower. If any engine requires 0.5lbs/hr for each 1 horsepower is outputs, it has a BSFC of 0.5. Calculating the actual BSFC of the n54 engine is well beyond the scope of this tech article. But for the sake of simplicity we are going to follow well-adopted rules of thumb. A typical naturally aspirated engine has a BSFC of 0.5. A typical mildly boosted engine (ie, one that runs slightly richer than an NA engine at WOT) has a BSFC of around 0.50-0.55. A higher boosted turbo engine (i.e., one that runs even richer at WOT), can easily have a BSFC of 0.55-0.65. We know our N54 isn’t a traditional high boost turbo engine that runs 10-11:1 AFR at full load, at 6000rpm (peak HP). Through the advantages of Direct Injection, it can happily run a bit leaner at, say 12:1 or thereabouts. Still richer than an NA engine. So let’s assume a target BSFC of 0.55. To see how much power our LPFPs can support, simply divide the flow numbers by 0.55. So if we revisit, the 11v @ 72psi test results (what actually we see in our cars), we get: Pump 1.... 228/0.55 or 415 Horsepower Pump 2.... 204/0.55 or 371 Horsepower Now let’s not forget that this represents approximate engine horsepower, NOT wheel horsepower a la Dynojet. So subtract another 30hp for driveline loss and you end up with: Pump 1.... 385whp Pump 2.... 341whp Impossible, I’m making more power than that! Yes, that may very well be the case. But it’s important to know that the theoretical max power numbers are just that, theoretical. And that it is very sensitive to BSFC. For instance, if we drop BSFC to just .50 (i.e., the engine runs a bit leaner than the desired AFR target), we end up getting much higher max power numbers: Pump 1.... 426whp Pump 2.... 378whp Stock LPFP Testing Summary: Fuel Flow (lbs/hr) @11v 43psi 72psi Pump 1 315 228 Pump 2 308 204 @14v 43psi 72psi Pump 1 442 356 Pump 2 430 300 Current (Amps) @11v 43psi 72psi Pump 1 8.2 9.3 Pump 2 8.3 9.8 @14v 43psi 72psi Pump 1 10.6 12.2 Pump 2 10.7 13.5 Next Up... PART 3 (UPGRADING THE FUEL SYSTEM!) Last edited by stressdoc; 04-13-2011 at 09:15 AM.. Reason: typos edited |

|

|

| 04-12-2011, 01:39 PM | #2 |

|

Brigadier General

1172

Rep 3,275

Posts |

subscribed

__________________

2022 BSM/FR M4 Competition X-Drive 2017 MW/SO M4 ZCP [SOLD] • 2015 MW/SO M4 M-DCT FBO [SOLD] • 2011 AW/CR 335is DCT FBO [SOLD] • 2008 AW/CR 335i 6MT FBO [SOLD] |

|

Appreciate

0

|

| 04-12-2011, 01:41 PM | #3 |

|

Legit :)

17

Rep 369

Posts |

awesome

__________________

|

|

Appreciate

0

|

| 04-12-2011, 01:50 PM | #6 |

|

Lieutenant

41

Rep 565

Posts |

Looking good. This is like a porno. Can we undress already.

__________________

08 E90 335i AT RB Turbos -NX Wet Kit - Chiplogic Flash or Procede V5- M3 Diff - AE Exhaust- Forge Dv's - Helix Intercooler - AR DP's - P3 Boost Gauge - Vishnu Meth- Stett Chargepipe and CAI

09 C63 |

|

Appreciate

0

|

| 04-12-2011, 01:55 PM | #7 |

|

Major General

190

Rep 5,417

Posts |

|

|

Appreciate

0

|

| 04-12-2011, 01:59 PM | #9 |

|

Major

83

Rep 1,283

Posts |

Shiv,

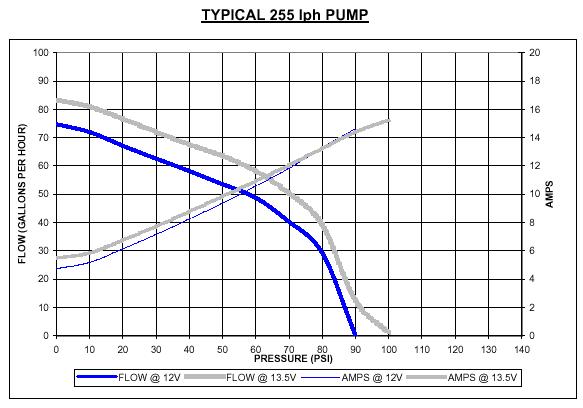

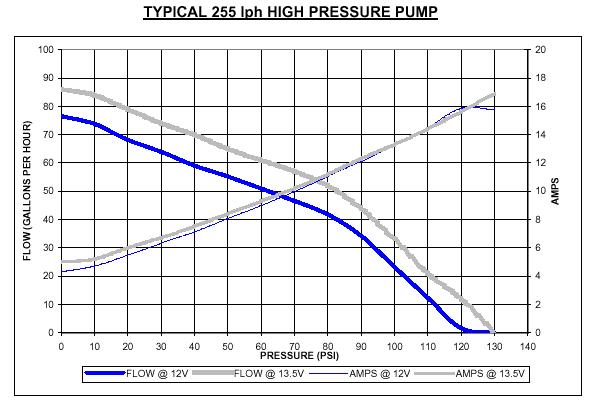

It looks like we are using a 255lph pump in this application, here's a graph from a walbro 255lph pump. Knowing that gasoline is 6.073 lb/gal and that the factory pump is pushing out 315lbs(52gal/hr) fuel per hour at 43 psi, 11 volts with an 8.2 amp draw. Looking at the walbro graph at 12 volts(you can extrapolate where the 11 volt line would be) I'd say it's pretty close in regards to flow and amp draw!  Potentially swapping in the better flowing 255 high pressure pump may be the answer to bring the fuel ceiling up about 20% at the same voltage levels with an even better amperage draw!  |

|

Appreciate

0

|

| 04-12-2011, 02:04 PM | #11 |

|

Major

164

Rep 1,304

Posts

Drives: 2020 M2 Comp, JB4

Join Date: Mar 2009

Location: Ontario, Canada

|

Sorry, but "holy shit it's up" from Sloppy "seconds" made me laugh....

__________________

2020 M2 Competition HS, DCT, 763s, Carbon: splitter, side skirt, grill, diffuser, wing

Previous: 2014 BMW F32 435iX - JB4, MHD Flash, BMS Meth Kit, ER Intercooler, intake, catless DPs, KW Streets, 437M Reps with 245/35 and 275/30 Michelin PSS 4S |

|

Appreciate

0

|

| 04-12-2011, 02:05 PM | #12 |

|

Major

30

Rep 1,041

Posts |

I think I need a new fuel pump asap....

Subscribed

__________________

E92 335i 2008 Space Grey 6MT | Pure Stage 2 turbos | Motiv PI | Trueform Tech Intake | Quaife LSD | M3 Suspension kit | Öhlins Road & Track Coilover | DEFIVfab N54 diff lockdown kit | COBB PTF E85 Map | Fuel-It Stage 3 LPFP | NGK 5992 plugs | Wagner FMIC | Wagner 3" DP | Milltek exhaust | Tial BOV | SPEC Stage 3+ clutch | SPEC Steel SM Flywheel |

|

|

Appreciate

0

|

| 04-12-2011, 02:12 PM | #17 |

1864

Rep 17,960

Posts

Drives: A Lot

Join Date: Sep 2006

Location: SF Bay, CA

iTrader: (0)

Garage List 2018 Ducati Panigal ... [0.00]

2016 Mazda CX5 [0.00] 2017 Aprilia Tuono ... [0.00] 2019 BMW M2 Competi ... [0.00] 2015 BMW M5 Competi ... [10.00] 2016 Ducati XDiavel S [0.00] 2016 AMG GT S [0.00] 2011 Ferrari 458 It ... [0.00] 2017 Charger Hellcat [0.00] 2015 KTM Super Duke ... [0.00] 2016 KTM RC390 [0.00] |

I'd never put a walbro 255 (high pressure) in a car again. We used to sell them for our Subaru turbo kits back in the day. Out of 100 that would be delivered to me, at least 10 just wouldn't work. And out of the remaining 90, at least 20 would be returned/exchanged due to excessive whining.

Shiv |

|

Appreciate

0

|

| 04-12-2011, 02:15 PM | #18 | |

|

Major

83

Rep 1,283

Posts |

Quote:

|

|

|

Appreciate

0

|

| 04-12-2011, 02:17 PM | #19 | |

1864

Rep 17,960

Posts

Drives: A Lot

Join Date: Sep 2006

Location: SF Bay, CA

iTrader: (0)

Garage List 2018 Ducati Panigal ... [0.00]

2016 Mazda CX5 [0.00] 2017 Aprilia Tuono ... [0.00] 2019 BMW M2 Competi ... [0.00] 2015 BMW M5 Competi ... [10.00] 2016 Ducati XDiavel S [0.00] 2016 AMG GT S [0.00] 2011 Ferrari 458 It ... [0.00] 2017 Charger Hellcat [0.00] 2015 KTM Super Duke ... [0.00] 2016 KTM RC390 [0.00] |

Quote:

The closer we dug into it, the more work ended up being required. We tested several options. |

|

|

Appreciate

0

|

| 04-12-2011, 02:25 PM | #22 |

|

Lieutenant Colonel

390

Rep 1,571

Posts |

Great results from a slight voltage increase. Looks like a piggyback to the EPK would free up alot more HP in fuel. Great work collecting data and sharing for the benefit of the platform.

|

|

Appreciate

0

|

|

| Bookmarks |

|

|